ASME PCC-1-2022 – is your flange tagging compliant?

ASME (American Society of Mechanical Engineers), have recently revised their PCC-1 guidelines for Pressure Boundary Bolted Flange Joint Assembly.

Here's what has changed and how it may affect the compliance of your current flange tagging systems.

ASME (American Society of Mechanical Engineers), have recently revised their PCC-1 guidelines for Pressure Boundary Bolted Flange Joint Assembly.

This document, written by engineers, scientists, and business executives across the bolting industry, addresses the key factors involved in bolting principles and the assembly of bolted flange joints. Essentially, anyone involved in the refinery, chemical, or pipeline industries who deal with assembling bolting connections, should be aware of this document. ASME PCC-1 is considered the standard for bolting joint connectors within many major petro-chemical companies worldwide.

Section 13 of the PCC-1-2022 document covers guidelines for recording bolted flange joint assembly - an important process to ensure leak free start-ups and workplace safety. For this section, ASME have worked with REGLATAGS to develop the multipart tear-off flange tag. This Tag has been used in the document to demonstrate compliant tagging for joints of all risk levels. This document also mentions four other types of flange tags are suitable for use on joints of low risk levels, and high risk levels, which we look further into here.

In light of this, we wanted to set out what has changed in the guidelines for joint assembly records, (sometimes known as torque tags) and how these changes may affect the compliance of your current flange tagging systems, and what you can do to ensure your processes remain safe and efficient.

ASME PCC-1-2022: What are the purposes of flange tags?

According to the revised PCC-1 guidelines, joint assembly records (Flange Tags) serve the following three purposes:

- Quality Control: Joint assembly records document the name and actions of each person responsible for a particular portion of the joint assembly process. This allows for better accountability if an incident occurs.

- Joint History: Joint assembly records document past assembly processes, observations made during the assembly, and lessons learned. This will allow future joint assemblers to mitigate the risk of a leak and look for guidance if there is one.

- Assembly Practices: Joint assembly records show all joint-specific practices, and deviations from, changes to, comments, and observations about the site assembly procedure. This data can be gathered by work personnel to update the assembly procedure before the next joint maintenance activity.

ASME PCC-1-2022: What information should flange tags include?

According to section 13 of the PCC-1-2022 document, the user should decide the details required in the joint assembly records, based on the “relative probability and consequences of a leak”. Guidance on the information flange tags may include are as follows:

- Joint location or identification

- Joint class and size

- Spec and condition of flanges, washers, and gaskets

- Date of activity

- Names of assemblers and workers

- Name of inspector or person responsible for the quality assurance and control of the joint

- Disassembly method

- Leak history

- Blots, nuts, and washers used

- Flatness measurements when made

- Assembly procedure and tightening method used

- Unanticipated problems and their solutions

- Tool data

- Recommendations for future assembly procedures and joint maintenance repairs

ASME PCC-1-2022: What are considered to be compliant Joint Assembly Record Tags?

As mentioned above, the information needed on joint assembly record tags depends on the needs and resources of the user, and the risk level of the joint.

It is advised a joint criticality analysis is carried out to determine the likelihood and consequence of failure for any given joint. Once this process has been carried out and the risk level of each joint has been declared, it will inform the level of record needed for them.

Based on each individual joints risk level, the user may follow one of the below paths for tagging:

- For joints deemed high risk, a long assembly record will be used

- For joints deemed lower risk, a short or medium length assembly record tag will be used

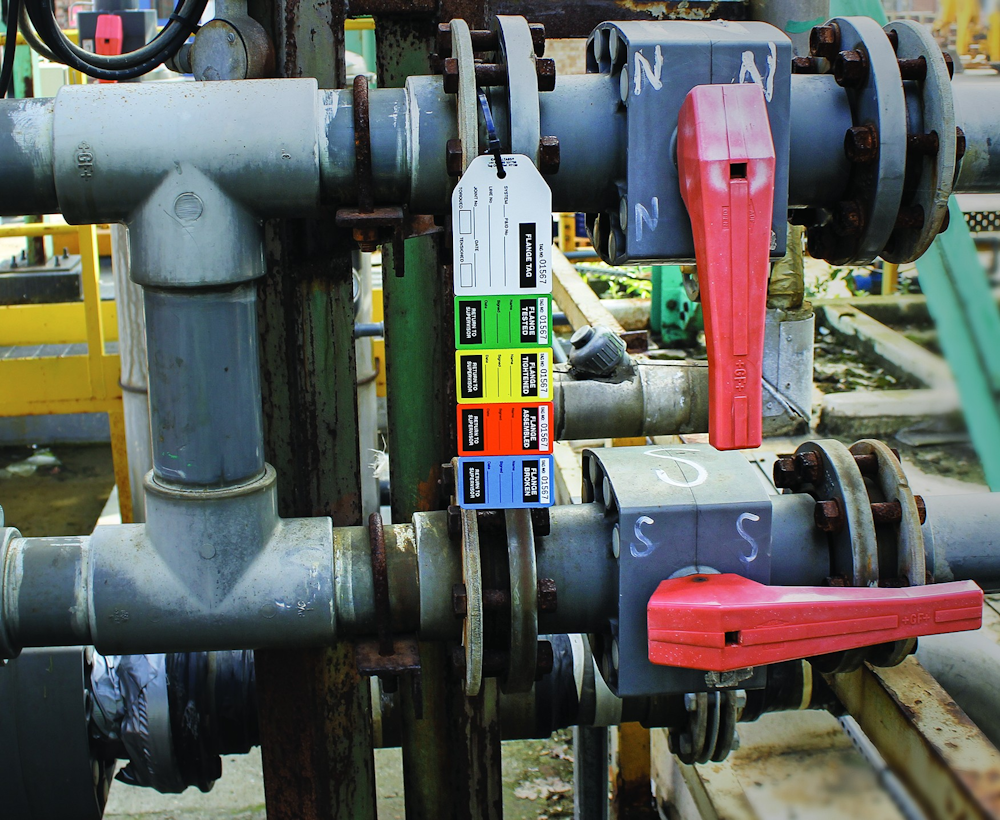

These tags should be clear, easy to read, and durable to withstand the harsh environments they are placed in.

Achieve Zero Incidents, and Joint Assembly Record compliance with REGALTAG

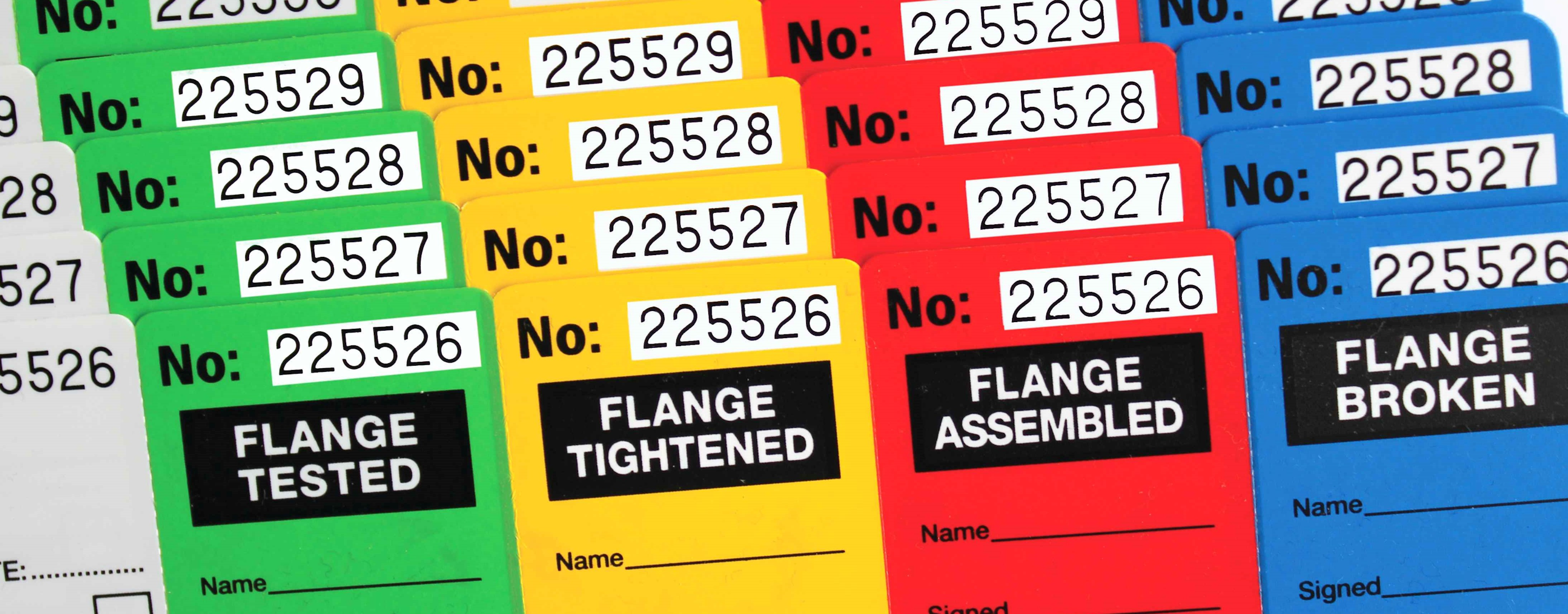

In the latest PCC-1 document, our multipart tear-off FLANjTAGS® have been recommended as being compliant for joints of “all risk levels”. These tags provide a highly visual status record to show that all steps of the flange break process have been safely carried out. The sequentially numbered tear-off sections provide visual evidence of each step being carried out and can be retained as an effective audit trail.

More on REGALTAG

We help companies in harsh environments reach Zero; that’s Zero incidents and Zero emissions.

Our Flange Tags are all UV resistant and freeze proof. They can be relied upon in all conditions to perform their critical safety role.

They’re also 100% recyclable and manufactured in our zero-to-landfill facilities to ensure you receive the most environmentally friendly system.

Our flange tags are also:

- Fully customisable – we work with customer to ensure the tag fully meets their current flange management procedures

- Available with QR codes / barcodes

- Made from ISO 4892-2:2013 Tested Material

- Available with VARiTAG® unique numbering

- Available in bilingual or dual languages

Request your sample of the ASME compliant multi-part Flange Tag or get in touch to discuss your flange tagging system in more detail.

Subscribe

Join 10,000+ others receiving our monthly updates. Free Tag knowledge delivered straight to your inbox.